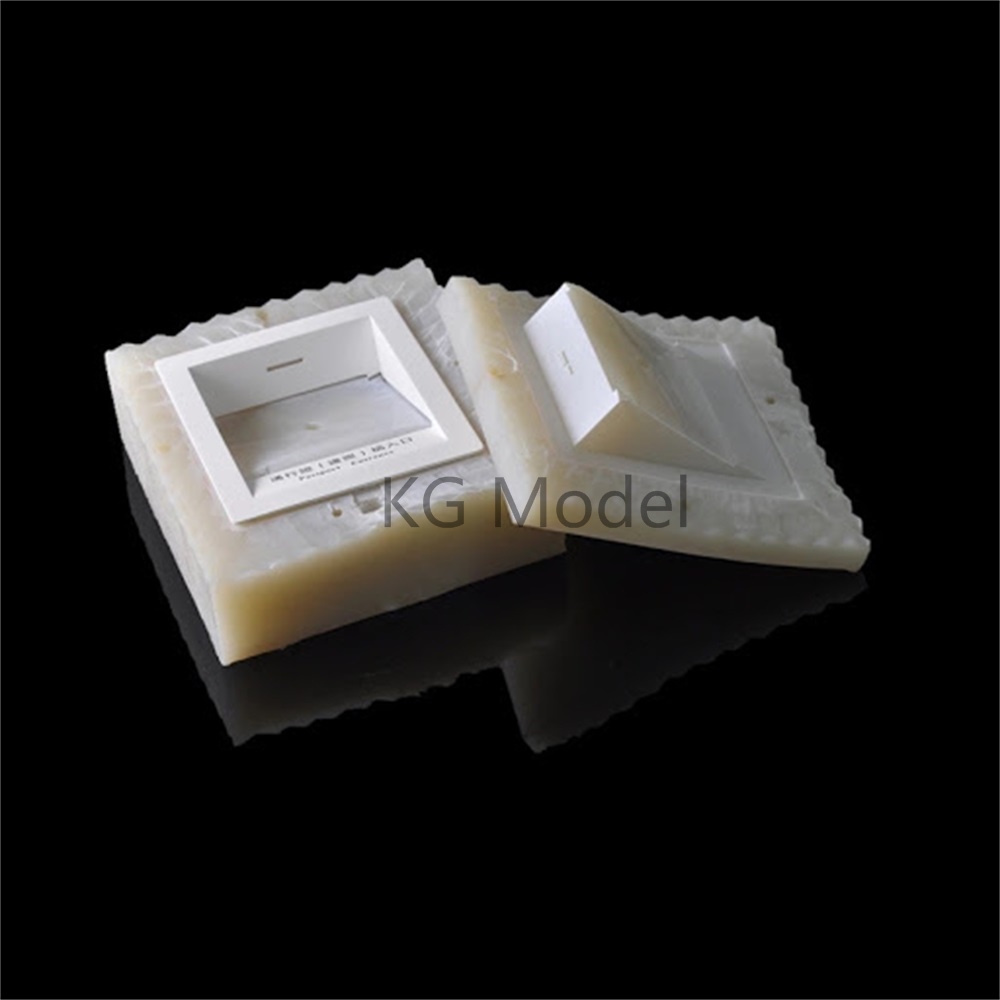

VACUUM CASTING

Our PU castings are not painted after vacuum casting. All of our castings pick up their polish ( gloss or matt ) or Mold-Tech or VDI texture directly from the RTV silicone mold and we pigment our high quality vacuum casting resins to match your color by RAL, Pantone requirement. And provide you a high quality marketing samples.

Vacuum Casting process starts by placing a two piece silicone mold in a vacuum chamber. The raw material is mixed and degassed and then poured into the mold. The vacuum is then released and the mold removed from the chamber. Finally, the casting is cured in an oven and the mold removed to release the completed casting. The silicone mold can be reused, making vacuum casting the perfect choice for small batch production.